In the industrial heartlands of Germany, where factory hums once echoed, a troubling silence has settled. Several European auto parts suppliers have shuttered production lines, hit hard by China’s April decision to restrict exports of rare earths—critical minerals powering everything from windshield wiper motors to electric vehicle batteries. As Beijing tightens its grip on 90% of the world’s rare earth supply, companies like BMW warn of disruptions rippling through their supply chains, leaving workers idle and carmakers scrambling. With inventories dwindling, Europe’s auto industry faces a crisis that could stall production across the continent.

China’s export curbs, targeting heavy rare earths like dysprosium, terbium, and samarium, have upended global supply chains, affecting automakers, aerospace firms, and military contractors. The restrictions, seen as retaliation for U.S. President Donald Trump’s tariffs of up to 145% on Chinese goods, require export licenses, but only 25% of hundreds of applications since April have been approved, often rejected on “highly procedural grounds,” according to Europe’s auto supplier association CLEPA. “The process is a maze—provinces have different rules, and some demand sensitive intellectual property details,” said a CLEPA spokesperson, warning of more outages in the next three to four weeks as stocks run dry. BMW reported its supplier network is affected, though its plants are still running, while Volkswagen noted some subcontractors secured limited licenses, avoiding immediate shortages.

In a Stuttgart factory, worker Anna Schmidt, 42, stood by a silent assembly line, her hands idle for the first time in years. “We make motors for car windows, but without rare earths, we’re stuck,” she said, her voice heavy with worry about job security. Across Europe, the auto sector, which employs 13 million and accounts for 7% of GDP, is reeling. CLEPA reports several plants have halted output, with more at risk. Swedish supplier Autoliv, the world’s top airbag and seatbelt maker, is unaffected but has formed a task force to monitor the crisis, its CEO Mikael Bratt said.

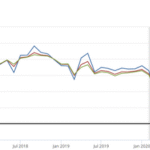

The context is stark. China’s move, part of a trade war with the U.S., has global reach, hitting Europe, India, and Japan. Trump’s tariffs, scaled back after market selloffs, prompted China’s response, but the curbs affect all nations, exposing Europe’s reliance on Chinese rare earths. Efforts to reduce dependency, like BMW’s magnet-free motors for electric cars, are underway, but scaling remains costly, and smaller components like wiper motors still need rare earths. “Companies feel abandoned by politicians and are scrambling for solutions in China,” said a German industry insider, frustration evident. Diplomats and executives from Europe, India, and Japan are pressing Beijing for faster approvals, but progress is slow.

Reactions reflect mounting concern. “This could choke our industry,” said Luca Rossi, a manager at a Turin parts supplier, fearing layoffs if shortages persist. German trade groups, like the VDA, warn production could halt entirely without swift action. In contrast, some see opportunity: Phoenix Tailings, a U.S. firm recycling rare earths from electronic waste, plans to scale production to 4,000 metric tons by 2027, spurred by the crisis. Yet, with China controlling 99% of heavy rare earth processing, alternatives remain limited.

The implications are dire. Shortages threaten not just cars but defense systems, like F-35 jets, reliant on rare earth magnets. Europe faces potential price hikes and job losses, with India’s auto sector also warning of imminent shutdowns. A looming Trump-Xi Jinping call this week could address the curbs, but Trump’s team calls China’s stance “tough” and deal-making difficult. The EU is exploring tariffs on U.S. goods like whiskey if talks fail, echoing past trade spats.

Looking ahead, Europe’s auto industry is racing against time. The EU is pushing for diversified supply chains, with Australia and Vietnam eyed as potential sources, but scaling takes years. CLEPA urges streamlined Chinese licenses to avoid further plant closures. Questions linger: Can diplomacy unlock China’s grip? Will Europe’s auto sector weather the storm, or face a deeper crisis? For now, as factories fall quiet and workers like Anna wait, the continent holds its breath, hoping for a breakthrough to keep its engines running.